Reverse Engineering Laboratory

Reverse Engineering and Metrology Lab

Reverse engineering (RE) is a critical activity for determining how products are designed and function. The advantages of reverse engineering have made it possible to investigate outdated design data for products with no valid details. Manufacturers consider reverse engineering to be a valuable tool for fostering innovation and for identifying and correcting design flaws. It is usually defined as a method of reproducing an existing part, subassembly, or product without the use of sketches, documents, or computer-aided design (CAD) models. It is used for a variety of applications, particularly gathering technical and engineering specifications for products and inspecting them. These requirements may be used to obtain a product's CAD model and do the necessary technical research to improve the design.

RE is paramount in a variety of applications, including the reconstruction of high-value antique parts for historical preservation, recovering the damaged or missing portion of a component, product design analysis, verification of fabricated product accuracy, generation of three-dimensional mockup to minimize the production time, enhancing the competitiveness of the new or existing product, and so on.

Hundreds of products have been successfully reverse-engineered in our facility and our professional engineers can produce the design requirements needed to manufacture the product. We can also offer ideas and recommendations to help you develop the overall production process.

Industries, labs, and businesses of all sizes can profit from AMI's dedicated RE and metrology facility.

The lab is equipped with cutting-edge tools and equipment, such as a Bridge-type Coordinate Measurement Machine, Portable Arm CMM, Handheld 3D scanners, etc.

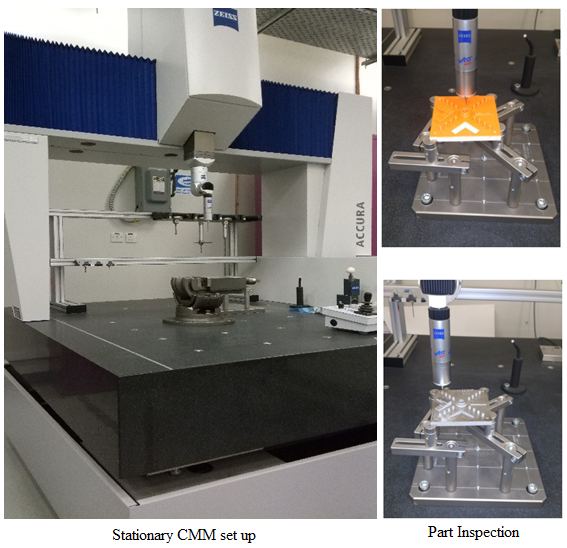

1.Stationary Coordinate Measurement Machine

It is a bridge type coordinate measuring machine (CMM) that can be used to accurately measure a variety of industrial parts such as car parts, aerospace components, turbine blades, medical devices. Its inspection services can be utilized to streamline the manufacturing process in order to minimize or eradicate quality issues. It is a medium-sized CMM employed that has an accuracy of (1.6 + L/333) μm, which complies with DIN EN ISO 10360-2:2001. This machine can accommodate small to medium sized work pieces measuring up to (1200 mm × 900 mm × 700 mm). It can be equipped with both contact and non-contact probes. It can be utilized in high precision measurements, dimensional and Surface inspection - Flatness, thickness, parallelism, perpendicularity, angularity, circularity, straightness, symmetry, cylindricity, etc., as well as reverse engineering.

Stationary Coordinate Measurement Machine

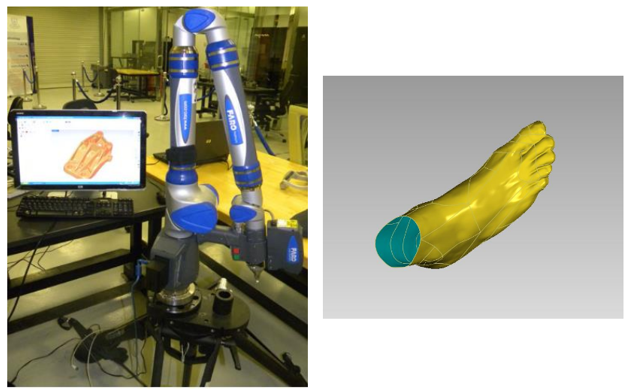

2.FARO Platinum Arm – Portable CMMIndustries such as aerospace, automotive, metal fabrication and tool & die manufacturing can take the services of the Faro Arm for dimensional analysis and quality control in numerous applications such as rapid prototyping, first article inspection, part verification and reverse engineering. It provides greater flexibility and dexterity to the user. The laser line scanning probe incorporated with a portable arm CMM provides an accuracy up to 40 µm under ideal conditions as specified by the manufacturer. It has a measuring range up to 6 feet and can scan up to19,200 points/s. The system output is compatible with a number of commercially available software such as Geomagics, Polywords, and Rapid form, etc. This set up can be utilized to fully capture the geometric features and freeform surfaces of any component.

FARO Platinum Arm – Portable CMM

3.Portable Handheld 3D scanners

Portable handheld scanners have been amongst the favored digitization technologies. Handheld 3D scanners are preferred over non-transportable alternatives by researchers and industries owing to their low weight and greater portability. Modern handheld 3D scanners that can scan very large objects both outdoors and within the lab are also available in the lab. They have incredibly high resolution and can detect even the smallest details. They build exact 3D objects and offer unmatched accuracy. These scanners can provide accuracy up to 0.05 mm under ideal conditions. They have applications in automotive, aerospace, die/mold design, healthcare, etc., industries.

Portable Handheld 3D scanners

4.Thunk 3D Scanner

It is a competent 3D scanner that has been designed and configured for use in applications requiring scanning of small objects. It has the ability to convert any type of physical object into a highly accurate digital replica. It incorporates automated scanning with a build size of 5 to 80 mm and scanning accuracy less than 10 mm.

Thunk 3D Scanner

5. Next Engine Desktop 3D scanner

It is a professional desktop 3D scanner developed by the US company NextEngine. It utilizes a rotating table and works on the principle of laser triangulation technology. A full 3D scan can be finished in up to 10 minutes and has an acquisition speed of 50,000 points/s. Its scanning areas are 342.9 x 256.54 mm (far) and 129.54 x 96.52 mm (near). It offers a maximum accuracy of 0.125 mm and a maximum resolution of 0.1 mm.

Next Engine Desktop 3D scanner