Research Groups

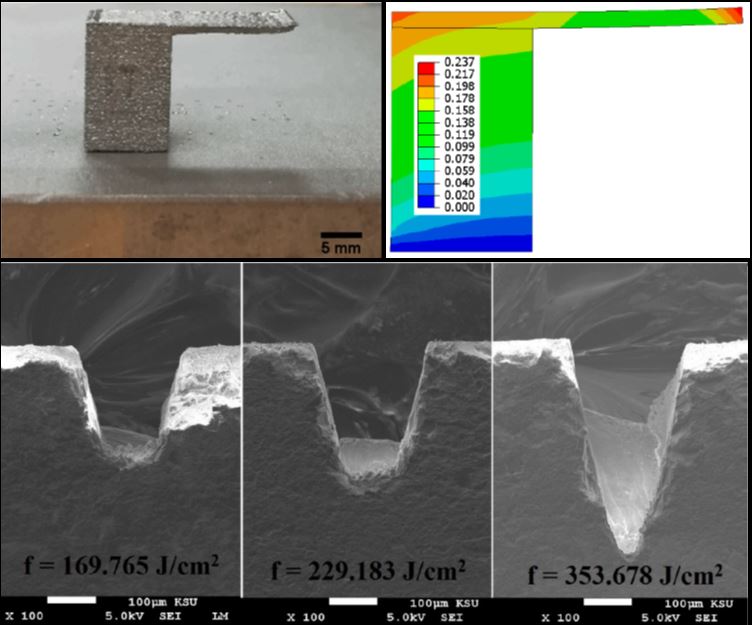

Title: Advanced Manufacturing

PI: Dr Usama Umer

Abstract:

This research group aims to mitigate the gap between theoretical research and the more practical oriented research on advanced manufacturing technologies including non-conventional and digital manufacturing. In several industries, hard and brittle materials such as high speed steels, stainless steels, tungsten carbide, ceramics etc., find a variety of applications. These materials are very hard to cut with the conventional manufacturing processes. Even after machining, the quality of the product is not good, therefore, to solve the issue, advanced manufacturing technologies including non-conventional machining processes, such as laser machining, Electro-Discharge machining (EDM), Electro-Chemical machining (ECM), Water-jet machining, Ultrasonic machining, etc. are used. Moreover, digital manufacturing which covers a bigger umbrella and includes additive manufacturing, CAD/CAM, rapid prototyping (RP), finite element analysis, and virtual reality (VR) is another advancement in manufacturing domain which solves several problems that are faced in conventional processes. Due to this fact, advanced manufacturing technologies including non-conventional processes and digital manufacturing are a hot topic among the industrial and academic researchers regarding concerns such as design, prototypes or manufacturing.

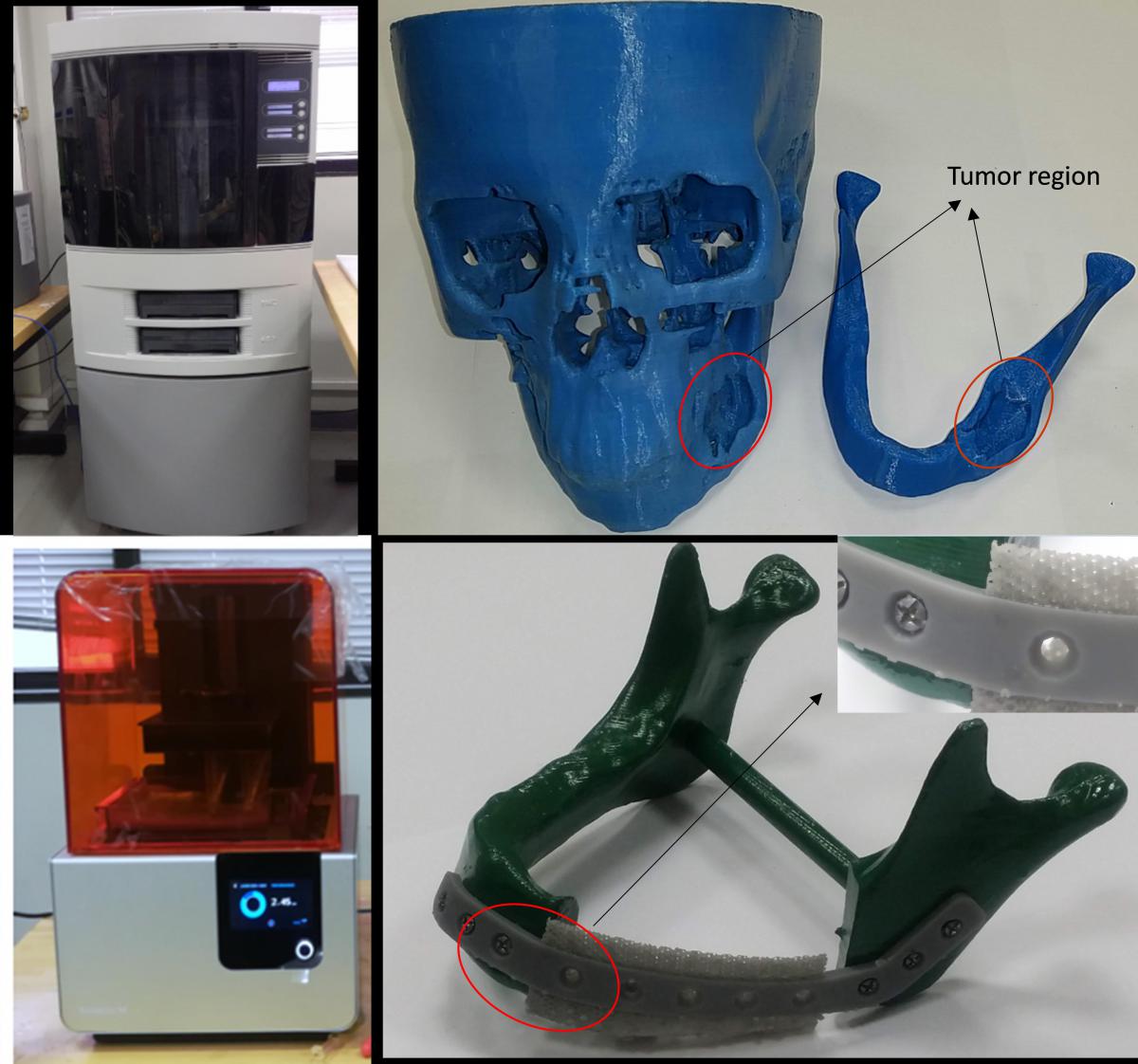

Title: Additive Manufacturing in Biomedical Applications

PI:Dr Khaja Moiduddin

Abstract: The main objective of this research group is to digitize the customization of medical implants and its fabrication using additive manufacturing process. Additive Manufacturing (AM) is gradually starting to attract interest in medical applications due to its cost effective production, customization and faster delivery. The introduction of AM to a digital workflow, decreases the lead time by speeding the work flow of patient diagnostic information between the surgeon and the laboratory. The customized implants produced through AM techniques from the patients computed tomography and magnetic resonance imaging scans can drastically reduce the implant failure and the number of revisions, thus minimizing the psychological stress and pain to the patient.